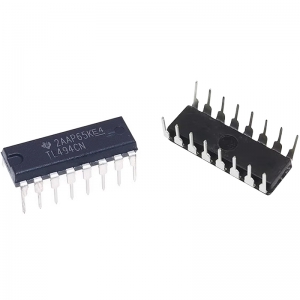

DIP-16 (Dual inline Package with 16 pins) is a traditional form of integrated circuit packaging widely used in early electronic devices and modern amateur electronic production, education, and prototype design. DIP packaging is named after its dual inline pin layout, which allows ICs to be directly inserted into sockets on printed circuit boards (PCBs) or fixed by manual soldering.

characteristic:

Direct insertion design: The pins of the DIP package are straight and can be inserted into corresponding sockets or pads from both sides, making it convenient for manual installation and disassembly.

Standardized size: The size of DIP packaging usually follows certain industrial standards, making it easier to design and manufacture.

Easy to repair and replace: Due to the fact that DIP packaging can be directly inserted into sockets or fixed by soldering, it is relatively easy to repair and replace.

Suitable for manual operation: DIP packaging is suitable for small batch production and manual welding, especially in education and personal projects.

Structure:

The structure of the DIP-16 package includes a rectangular plastic or ceramic casing, with two parallel rows of straight pins protruding from both sides of the package. Each row has 8 pins, totaling 16 pins. The pitch is usually 0.1 inches (2.54 millimeters), which is the standard pitch for DIP packaging.

Size:

The size of DIP-16 packaging may vary depending on the specific manufacturer and product model, but usually follows the following standard dimensions:

Package length: usually between 20mm and 30mm.

Package width: usually between 7mm and 10mm.

Packaging thickness: usually between 3mm and 5mm.

The length and width of pins may also vary according to standards, but they are usually designed to be sturdy enough to withstand thermal and mechanical stresses during the welding process.

Application:

DIP-16 packaging is suitable for various integrated circuits, including logic gates, counters, shift registers, operational amplifiers, comparators, analog switches, timers (such as 555 timers), etc. Due to its ease of manual operation, DIP packaging is particularly popular in teaching, experimentation, and small projects.

matters needing attention:

When using DIP-16 packaging, the following points should be noted:

Welding process: When manual welding, it is necessary to ensure that the pins are correctly aligned and the welding quality is good to avoid short circuits or open circuits.

Compatibility of sockets: If using sockets, it is necessary to choose sockets that are compatible with DIP-16 packaging and ensure reliable contact of the sockets.

Thermal management: Although DIP packaging is not specifically designed for thermal management, heat dissipation issues still need to be considered in high-power applications.

When selecting DIP-16 packaging, reference should be made to the manufacturer's data manual and application notes for detailed dimensional information, recommended design guidelines, and welding process parameters. Although DIP packaging has gradually been replaced by more advanced SMT packaging, it is still a practical choice in certain specific applications.

Shenzhen Baoxin Chuang Electronics Co., Ltd.

Address: 45th Floor, SEG Plaza, 1002 Huaqiang North Road, Futian District, Shenzhen, Guangdong, China

Website: www.boxintron-ic.com

Tel: +86-0755-8355 3623/8322 8690/8322 8629/8322 8357

Fax: +86-0755-8366 0820

Email: service@boxintron.com

Electronic components with a single expert

Shenzhen Baoxin Chuang Electronics Co., Ltd. is committed to becoming the best IC supplier with single expert and IC agent

Strive to provide customers with one-stop electronic components procurement and IC supporting services

Tel: +86-0755-8355 3623 Fax Fox: +86-0755-8366 0820 Email: service@boxintron.com

Address: Room 4503, 45th Floor, SEG Plaza, 1002 Huaqiang North Road, Futian District, Shenzhen, Guangdong, China

![Shenzhen Baoxin Chuang Electronics Co., Ltd. [one-stop type of electronic components with one-only original authentic] Shenzhen Baoxin Chuang Electronics Co., Ltd. [one-stop type of electronic components with one-only original authentic]](templates/web/images/logo.png)