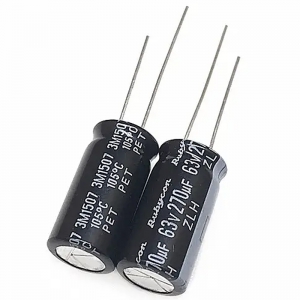

Through hole electrolytic capacitors, also known as radial lead electrolytic capacitors, are capacitors that use electrolytes as the dielectric. This type of capacitor is widely used in the electronics industry due to its high capacitance value, volume ratio, and relatively low cost. Direct insertion electrolytic capacitors are mainly made of aluminum or tantalum materials, among which aluminum electrolytic capacitors are the most common.

characteristic:

High capacitance value: Electrolytic capacitors can provide a high capacitance value, ranging from a few microfarads to several thousand microfarads.

Volume ratio: Compared to other types of capacitors, electrolytic capacitors typically have smaller volumes at the same capacitance value.

Polarity: Electrolytic capacitors are polarized components that must be correctly connected to the circuit, with the positive (+) connected to a high potential and the negative (-) connected to a low potential, otherwise it can cause damage or even explosion to the capacitor.

Wide voltage range: Electrolytic capacitors have a wide range of available voltages, ranging from a few volts to several hundred volts.

Limited lifespan: The service life of electrolytic capacitors is affected by electrolyte drying and aging, and is usually not as long as non electrolytic capacitors.

Application:

Power filtering: Electrolytic capacitors are commonly used for filtering power lines to reduce electromagnetic interference and improve power quality.

Coupling and decoupling: In amplifiers and other analog circuits, electrolytic capacitors are used for signal coupling and decoupling.

Smooth voltage: After rectifying the circuit, the electrolytic capacitor is used to smooth the output voltage and eliminate ripple.

Energy storage: In some applications that require instantaneous energy release, electrolytic capacitors can store energy and quickly release it when needed.

Type:

Electrolytic capacitors are mainly divided into two types:

Aluminum electrolytic capacitor: uses aluminum foil as the anode, aluminum oxide layer as the medium, and the electrolyte is usually liquid.

Tantalum electrolytic capacitor: using tantalum metal as the anode and tantalum oxide layer as the medium, the electrolyte can be solid or liquid.

Packaging and dimensions:

The packaging of inline electrolytic capacitors usually refers to the diameter and length of their casing, as well as the spacing between the leads. Common sizes include:

Small: Diameters range from 4mm to 10mm, and lengths range from 5mm to 15mm.

Medium size: Diameters range from 10mm to 20mm, and lengths range from 15mm to 40mm.

Large: with a diameter exceeding 20mm and a length possibly exceeding 40mm, suitable for specific high-power or high-voltage applications.

When selecting a direct insertion electrolytic capacitor, factors such as capacitance value, operating voltage, polarity, temperature range, lifespan, and cost need to be considered. Manufacturers usually provide detailed product specifications and data sheets to help users make appropriate choices. Due to the wide variety of electrolytic capacitors, the most suitable electrolytic capacitor product should be selected based on specific circuit design and space limitations. Meanwhile, due to the polarity of electrolytic capacitors, special attention should be paid to their correct polarity connection when designing and assembling circuits.

Shenzhen Baoxin Chuang Electronics Co., Ltd.

Address: 45th Floor, SEG Plaza, 1002 Huaqiang North Road, Futian District, Shenzhen, Guangdong, China

Website: www.boxintron-ic.com

Tel: +86-0755-8355 3623/8322 8690/8322 8629/8322 8357

Fax: +86-0755-8366 0820

Email: service@boxintron.com

Electronic components with a single expert

Shenzhen Baoxin Chuang Electronics Co., Ltd. is committed to becoming the best IC supplier with single expert and IC agent

Strive to provide customers with one-stop electronic components procurement and IC supporting services

Tel: +86-0755-8355 3623 Fax Fox: +86-0755-8366 0820 Email: service@boxintron.com

Address: Room 4503, 45th Floor, SEG Plaza, 1002 Huaqiang North Road, Futian District, Shenzhen, Guangdong, China

![Shenzhen Baoxin Chuang Electronics Co., Ltd. [one-stop type of electronic components with one-only original authentic] Shenzhen Baoxin Chuang Electronics Co., Ltd. [one-stop type of electronic components with one-only original authentic]](templates/web/images/logo.png)