characteristic:

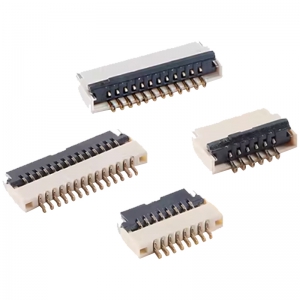

High density: FPC connectors are designed for high-density circuit board layouts, enabling fine-grained and miniaturized connections.

Flexibility: Due to the flexibility of FPC itself, FPC connectors support flexible circuit routing and connection requirements in three-dimensional space.

Easy to install: FPC connectors are usually designed to be easy to plug and unplug, making it easy to quickly install and replace FPCs during the production process.

Stability: FPC connectors provide stable electrical connections and maintain good contact performance even after multiple bends.

Structural composition:

The basic structure of FPC connectors includes:

Fixed part: This is the main body of the connector, usually fixed on a rigid circuit board, including pins and a plastic base.

Pin: Used to make contact with conductors on FPC, usually made of copper alloy, with a surface coated with gold or other corrosion-resistant metals.

Locking mechanism: Many FPC connectors are equipped with locking mechanisms to ensure the stable position of the FPC in the connector and prevent detachment caused by vibration or external forces.

usage method:

Choose the appropriate FPC connector: Choose an FPC connector with the appropriate spacing, height, and number of pins based on the specifications and application requirements of the FPC.

Install to circuit board: Weld the fixed part of the FPC connector onto the circuit board, ensuring that the welding points are secure and free of short circuits.

Insert FPC: Insert one end of the FPC into the FPC connector in the correct direction. If there is a locking mechanism, make sure it is locked in place.

Test Connection: After installation is completed, perform electrical testing to ensure good contact between the FPC and the connector.

Application:

FPC connectors are widely used in various electronic devices and systems, including:

Mobile phones and tablets

LCD display screen and touch screen

Digital cameras and camcorders

Medical equipment and instruments

Automotive Electronics and Aviation Electronics

FPC connectors have become one of the commonly used connection solutions for electronic engineers in designing and manufacturing compact and highly reliable electronic devices due to their high density, flexibility, and ease of installation. With the trend of miniaturization and lightweighting of electronic products, FPC connectors are increasingly widely used in modern electronic manufacturing industry.

Shenzhen Baoxin Chuang Electronics Co., Ltd.

Address: 45th Floor, SEG Plaza, 1002 Huaqiang North Road, Futian District, Shenzhen, Guangdong, China

Website: www.boxintron-ic.com

Tel: +86-0755-8355 3623/8322 8690/8322 8629/8322 8357

Fax: +86-0755-8366 0820

Email: service@boxintron.com

Electronic components with a single expert

Shenzhen Baoxin Chuang Electronics Co., Ltd. is committed to becoming the best IC supplier with single expert and IC agent

Strive to provide customers with one-stop electronic components procurement and IC supporting services

Tel: +86-0755-8355 3623 Fax Fox: +86-0755-8366 0820 Email: service@boxintron.com

Address: Room 4503, 45th Floor, SEG Plaza, 1002 Huaqiang North Road, Futian District, Shenzhen, Guangdong, China

![Shenzhen Baoxin Chuang Electronics Co., Ltd. [one-stop type of electronic components with one-only original authentic] Shenzhen Baoxin Chuang Electronics Co., Ltd. [one-stop type of electronic components with one-only original authentic]](templates/web/images/logo.png)