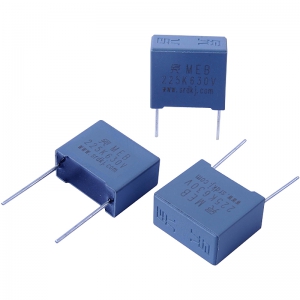

Film capacitors are a type of capacitor that uses plastic film as a dielectric. These capacitors are widely used in various electronic circuits due to their excellent electrical characteristics, stability, and reliability. The dielectric material of thin film capacitors can be polyester (PET), polypropylene (PP), polyphenylene sulfide (PPS), polycarbonate (PC), or other high-performance plastic films.

characteristic:

Low loss: Thin film capacitors have very low dielectric loss, which makes them perform well in high-frequency applications.

High stability: Thin film capacitors have excellent temperature stability and time stability, and the capacitance value has little drift with temperature and time.

High voltage resistance: Thin film capacitors can withstand high DC and AC voltages, making them suitable for high-voltage applications.

Non polarity: Thin film capacitors are non-polar capacitors that can be used in AC circuits.

Long lifespan: Due to the stability of its materials and the robustness of its structure, thin film capacitors typically have a longer service life.

Application:

Power filtering: Thin film capacitors are commonly used for filtering power lines to reduce electromagnetic interference and improve power quality.

Motor drive: In frequency converters and motor drive circuits, thin film capacitors are used to smooth the DC bus voltage.

Audio frequency division: In audio systems, thin film capacitors are used for frequency division networks because they can provide clear sound quality and accurate response.

RF coupling: In radio and communication equipment, thin film capacitors are used for coupling and decoupling RF signals.

Precision measurement: Thin film capacitors are an ideal choice for measuring equipment that requires high precision and stability.

Type:

Thin film capacitors can be classified into various types based on their structure and manufacturing process:

Metallized film capacitor: Using metallized plastic film as electrode, it has self-healing ability, that is, under overvoltage conditions, the local breakdown area will evaporate, thereby restoring the insulation performance of the capacitor.

Foil type thin film capacitor: Using metal foil as the electrode, it usually has higher voltage resistance and lower inductance.

Packaging and dimensions:

The packaging and size of thin film capacitors are diverse, including:

Radial lead type: This is the most common type, with leads at both ends of the capacitor, suitable for manual welding or automatic insertion.

SMT type: suitable for surface mount technology (SMT), with dimensions similar to other SMT capacitors.

Axial lead type: The two leads of a capacitor are led out from the same end, suitable for specific installation requirements.

Large cylindrical shape: used for high-power applications, with a larger size and sometimes with heat dissipation fins.

When selecting thin film capacitors, factors such as capacitance value, operating voltage, frequency response, temperature range, packaging size, and cost need to be considered. Manufacturers usually provide detailed product specifications and data sheets to help users make appropriate choices. Due to the wide variety of thin film capacitors, the most suitable thin film capacitor product should be selected based on specific circuit design and space limitations.

Shenzhen Baoxin Chuang Electronics Co., Ltd.

Address: 45th Floor, SEG Plaza, 1002 Huaqiang North Road, Futian District, Shenzhen, Guangdong, China

Website: www.boxintron-ic.com

Tel: +86-0755-8355 3623/8322 8690/8322 8629/8322 8357

Fax: +86-0755-8366 0820

Email: service@boxintron.com

Electronic components with a single expert

Shenzhen Baoxin Chuang Electronics Co., Ltd. is committed to becoming the best IC supplier with single expert and IC agent

Strive to provide customers with one-stop electronic components procurement and IC supporting services

Tel: +86-0755-8355 3623 Fax Fox: +86-0755-8366 0820 Email: service@boxintron.com

Address: Room 4503, 45th Floor, SEG Plaza, 1002 Huaqiang North Road, Futian District, Shenzhen, Guangdong, China

![Shenzhen Baoxin Chuang Electronics Co., Ltd. [one-stop type of electronic components with one-only original authentic] Shenzhen Baoxin Chuang Electronics Co., Ltd. [one-stop type of electronic components with one-only original authentic]](templates/web/images/logo.png)