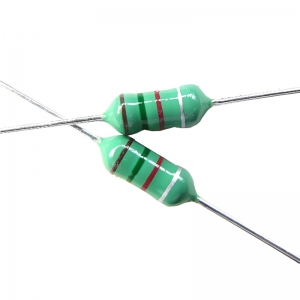

Color ring inductor, also known as color coded inductor or inductor with color ring, is a small inductor that represents its inductance value through color ring markings. This type of inductor is usually plug-in, with axial leads, suitable for through-hole mounting. The inductance value, tolerance, and sometimes even rated current of the color ring inductor can be determined by interpreting the color ring on its surface, similar to the reading method of the color ring resistor.

Color Ring Encoding System:

The coding system for color ring inductors is similar to that for color ring resistors, but not exactly the same. A color ring usually consists of several colored bands, each representing a number or a multiplier factor. However, it should be noted that not all color ring inductors follow a unified coding standard, and different manufacturers may have different coding rules. Therefore, before using color ring inductors, it is best to refer to the specific specification sheet or data manual provided by the manufacturer.

Common color ring coding examples:

First and Second Rings: The first and second significant digits representing the inductance value.

The third ring: usually represents the multiplier factor, which is how many zeros are added after the first two digits.

The fourth ring (if any): may represent the tolerance percentage of inductance.

For example, if the first two color rings of a color ring inductor are brown (1) and black (0), and the third color ring is red (multiplied by 10 ^ 2), then its inductance value is 10 x 10 ^ 2=1000 μ H (micro Henry). If the fourth color ring is golden, then its tolerance may be ± 5%.

characteristic:

Miniaturization: Color ring inductors are usually small in size, making them easy to use on circuit boards with limited space.

Cost effectiveness: Due to mature manufacturing processes, color ring inductors are often cost-effective and suitable for large-scale production.

Easy to recognize: The inductance value can be intuitively identified through the color ring, which is convenient for production and maintenance.

Application:

Color ring inductors are widely used in various electronic devices, including but not limited to:

Filter circuit: used to remove high-frequency noise in the circuit.

Coupling and decoupling: Used for signal coupling and decoupling in amplifiers and other analog circuits.

Oscillator: Used as a critical component in RC or LC oscillators.

Impedance matching: Used in RF circuits to adjust the impedance of the circuit for optimal performance.

The packaging and size of color coded inductors are relatively standardized, but may also vary depending on the manufacturer and specific application requirements. The following are some common packaging and dimensions for color ring inductors:

Common packaging and dimensions:

Axial Lead Inductors:

Dimensions: The diameter is usually between 1.0mm and 5.0mm, and the length is between 2.0mm and 10.0mm.

Features: Two leads are led out from both ends of the inductor, suitable for perforated installation.

Small axial lead inductance:

Size: Smaller size, such as 0805 (imperial) or 2012 (metric), suitable for compact designs.

Large axial lead inductance:

Size: A larger size, such as 1210 (imperial) or 3225 (metric), suitable for applications that require higher inductance and/or greater current.

Other relevant information:

Inductance value: The inductance value range of a color ring inductor can range from a few microvolts (μ H) to a few milliohms (mH).

Rated current: The rated current depends on the size and design of the inductor, and can range from a few milliamperes (mA) to a few amperes (A).

Tolerance: The tolerance is usually between ± 5% and ± 20%, depending on the type and manufacturer of the inductor.

Working temperature range: The general working temperature range may be between -40 ° C to+85 ° C or wider, depending on the material and structure of the inductor.

When selecting a color ring inductor, the following parameters need to be considered:

Inductance value: Determine the required inductance value based on the circuit design requirements.

Rated current: The maximum current that an inductor can safely withstand.

Direct current resistance (DCR): The inherent resistance of an inductor, which affects power loss and efficiency.

Self resonant frequency (SRF): The self resonant frequency of an inductor at high frequencies, beyond which the inductor will no longer exhibit ideal inductance behavior.

Size and packaging: Choose the appropriate size and packaging based on the actual installation space and process.

Due to the wide variety of color ring inductors, the most suitable color ring inductor product should be selected based on specific circuit design and application requirements. Meanwhile, considering the important role of color ring inductors in circuits, the stability of their quality and performance is crucial for the reliable operation of the entire system. In practical applications, factors such as the heat dissipation capacity of inductors, electromagnetic compatibility (EMC), and long-term stability should also be considered. Manufacturers usually provide detailed product specifications and data sheets to help users make appropriate choices.

Shenzhen Baoxin Chuang Electronics Co., Ltd.

Address: 45th Floor, SEG Plaza, 1002 Huaqiang North Road, Futian District, Shenzhen, Guangdong, China

Website: www.boxintron-ic.com

Tel: +86-0755-8355 3623/8322 8690/8322 8629/8322 8357

Fax: +86-0755-8366 0820

Email: service@boxintron.com

Electronic components with a single expert

Shenzhen Baoxin Chuang Electronics Co., Ltd. is committed to becoming the best IC supplier with single expert and IC agent

Strive to provide customers with one-stop electronic components procurement and IC supporting services

Tel: +86-0755-8355 3623 Fax Fox: +86-0755-8366 0820 Email: service@boxintron.com

Address: Room 4503, 45th Floor, SEG Plaza, 1002 Huaqiang North Road, Futian District, Shenzhen, Guangdong, China

![Shenzhen Baoxin Chuang Electronics Co., Ltd. [one-stop type of electronic components with one-only original authentic] Shenzhen Baoxin Chuang Electronics Co., Ltd. [one-stop type of electronic components with one-only original authentic]](templates/web/images/logo.png)