characteristic:

Flexibility: The pin arrangement provides flexible connection options, making it easy to establish temporary or permanent connections between different circuit boards or modules.

Easy to plug and unplug: The pin design is easy to plug and unplug, making it easy to test, debug, and replace components.

Standardization: The pitch between the pins usually follows standard dimensions such as 2.54mm (0.1 inches), 2.0mm, etc., which allows them to be used in conjunction with various standard sockets and jumpers.

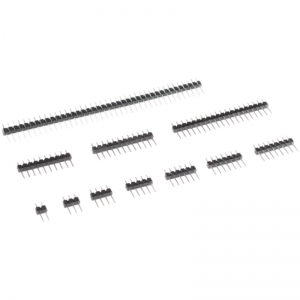

Multiple configurations: The pins can be single row, double row, or multi row, and the number of pins can also be customized according to needs.

Structural composition:

The basic structure of needle arrangement includes:

Pin: Usually made of copper alloy, it has good conductivity and elasticity, and the surface may be coated with gold, tin, or other metals to improve performance.

Base: The part that supports the pins, usually made of plastic or other insulating materials. There may be positioning slots or other mechanical features on the base to help with correct insertion.

Fixation method: The pins can be fixed on the circuit board through Through Hole or Surface Mount (SMT). Direct insertion pins are fixed in the holes of the circuit board by welding, while surface mount pins are directly soldered to the surface of the circuit board.

usage method:

Choose the appropriate pin arrangement: Select the appropriate spacing, number of rows, and number of pins according to the circuit design requirements.

Install to circuit board: Insert the pins into the corresponding holes on the circuit board (for direct insertion), or place them in the designated position on the circuit board (for surface mount).

Welding: Use a soldering iron to solder the pins of the pins onto the circuit board, ensuring that the soldering points are secure and free of short circuits.

Connect other circuit boards or modules: Align the sockets on another circuit board or module with the pins, gently push in, and complete the connection.

Application:

Pin arrangement is widely used in various electronic devices and systems, including:

Microcontroller and sensor module

Prototype development and breadboard experiments

Electronic Education Suite

Industrial control equipment

Consumer electronics products

Due to its simplicity, flexibility, and high cost-effectiveness, pin arrangement has become one of the commonly used connection solutions for electronic engineers in designing and manufacturing electronic devices. With the trend of miniaturization and integration of electronic products, the importance of needle arrangement in modern electronic manufacturing industry is increasing.

Shenzhen Baoxin Chuang Electronics Co., Ltd.

Address: 45th Floor, SEG Plaza, 1002 Huaqiang North Road, Futian District, Shenzhen, Guangdong, China

Website: www.boxintron-ic.com

Tel: +86-0755-8355 3623/8322 8690/8322 8629/8322 8357

Fax: +86-0755-8366 0820

Email: service@boxintron.com

Electronic components with a single expert

Shenzhen Baoxin Chuang Electronics Co., Ltd. is committed to becoming the best IC supplier with single expert and IC agent

Strive to provide customers with one-stop electronic components procurement and IC supporting services

Tel: +86-0755-8355 3623 Fax Fox: +86-0755-8366 0820 Email: service@boxintron.com

Address: Room 4503, 45th Floor, SEG Plaza, 1002 Huaqiang North Road, Futian District, Shenzhen, Guangdong, China

![Shenzhen Baoxin Chuang Electronics Co., Ltd. [one-stop type of electronic components with one-only original authentic] Shenzhen Baoxin Chuang Electronics Co., Ltd. [one-stop type of electronic components with one-only original authentic]](templates/web/images/logo.png)